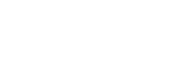

Hammer crusher

[ Product Brief]: The hammer crusher is a kind of equipment that crushes materials in the form of impact. It is divided into single rotor and double rotor. It is a section crusher that directly crushes materials with a maximum particle size of 600-1600 mm to 25 or less.

[Feed size]: 0-1600mm

[Production capacity]: 5-120t/h

[Scope of application]: It is suitable for fine crushing of medium hardness and brittle materials in mining, cement, coal, metallurgy, building materials, highways and other industries.