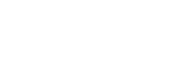

Hydraulic pressure Briquette Machine

[Product Brief]: Hydraulic Briquette Machine is mainly for making briquettes from powder materials, this series machine adopts a unique hydraulic system, so that improve the briquetting rate and strength.

[Working pressure from]: Hydraulic pressure

[Production capacity]: 1-120t/h

[Application material]: Kinds of powder materials, Mine powder, coal, charcoal powder, Gypsum powder, Sludge, iron oxide kiln, iron powder, aluminum oxide/clay and various refractory materials