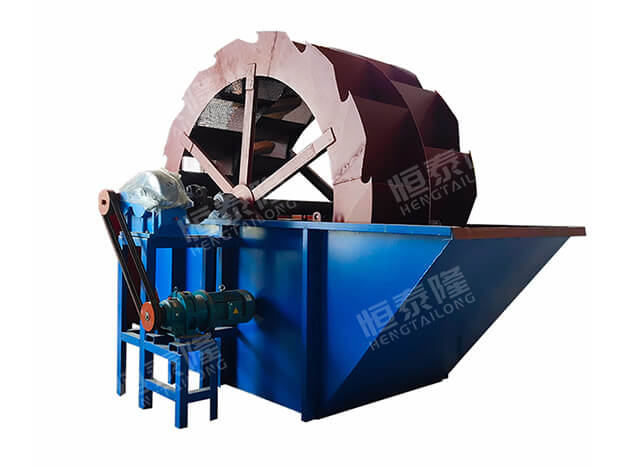

Bucket Wheel Sand washing machine is used to remove the dust in sand. Sand washer aims at improving the quality of sand. The materials include the required gravel in building-site, gravel factories, hydropower station and concrete dam site, post and electric pole factory, casting-70 sand, glass factory's quartz sand and refilling pressure sand.Bucket Wheel Sand washing machine is widely used for cleaning materials in the following industries: quarry, minerals, building materials, transportation, chemical industry, water conservancy and hydropower, cement mixture station. So we design this machine ,which is mainly used for washing , selecting dewatering construction materials and sand materials.

Working Principle

The electric motor runs slowly with the impellor after decelerated by the belt, decelerator and gears wheel. The sand and stone flow into washing launder from feeding launder, rolls with the impellor, and grinds each other. The impurity covering the sand is washing away. At the same time, add more water, the strong water flow will take away waste and some low-weight wastes from washing launder. Through the above process, the washing function is finished. The clean sand and stone is lift up by vane. When it goes up slowly, the water begins to drop through the mesh and fall back in the washing launder. On one hand, water is removed from the sand and stone; on the other hand, the water can be fully used. Finally, the sand and stone goes to the out launder from the rotary impellor to finish the washing task.

Feature:

The sand washing machine (bucket wheel sand washing machine) is widely used in washing, grading and impurity removal in metallurgy, building materials, hydropower and other industries, and is suitable for washing fine and coarse-grained materials. It is suitable for sand for construction and gravel for road construction. The sand washing machine has reasonable structure, convenient maintenance, large processing capacity, low power consumption and high degree of cleaning. The novel sealing structure, fully enclosed oil-bath type transmission device, and adjustable overflow weir plate ensure the high efficiency and durability of this series of products, good cleaning and dehydration effects, and the stability of fine-grained products.

-

1The structure of the machine is simple, and the impeller drive bearing device is isolated from water and water-receiving materials, which greatly avoids the bearing damage caused by water immersion, sand and pollutants.

-

2The sand washing machine (sand washing machine) has obvious advantages compared with the traditional spiral sand washing machine when it is used for sand washing in the gravel yard

-

3There is very little loss of medium-fine sand and stone powder, and the grade and fineness modulus of the washed building sand meet the national standards for "construction sand" and "construction pebbles and gravel".

-

4The machine has almost no wearing parts except screen.

-

5Long service life, no maintenance for a long time.