The Impact crusher can handle the material with the side length of 100-500 mm and can resist the pressure up to 350 mpa.Widely used in building materials, ore crushing, railway, highway, energy, transportation, energy, cement, mining, chemical and other industries used to fine materials.Its discharge particle size can be adjusted, crushing specifications diversification.

working principle :

The impact crusher is a kind of crushing machine which uses impact energy to crush materials.Machine work, under the drive of the motor, the rotor high-speed rotation, the material into the plate hammer function area, and the rotor plate hammer impact broken, and then again to counter device is broken, and then back to the board from the back plate hammer function area is broken again, this process is repeated, repeated material from big to small into the back cavity broken, until the material being broken to the required size, is being exhausted from port discharge.Stone from the upper part of the machine directly into the high-speed rotating rotary table;Under the action of high speed centrifugal force, high speed collision and high density crushing are produced with another part of flying stone which is separated in the way of umbrella around the rotary table. After the stone hits each other, it will form eddy current movement between the rotary table and the machine case and cause many times of mutual hitting and crushing.

Product Characteristics:

-

1The impact crusher is more effective in processing wet materials and effectively prevents material blockage.

When the water content of the processed material is too large, the feeding chute and the impact plate of the impact crusher can be equipped with heating devices to prevent the material from sticking. The impact crusher does not need to be equipped with a bottom sieve plate to effectively prevent clogging.

-

2The impact crusher is applicable to a wider range of material hardness.

The hammer of the impact crusher is mechanically clamped on the rotor and has a large moment of inertia when it rotates with the rotor. Compared with the hammer crusher (the hammer head is in a suspended state), the rotor of the impact crusher has a larger momentum, which is suitable for crushing harder materials, and they also have lower energy consumption.

-

3it is convenient and flexible to adjust the particle size of the discharge, and the adjustment range is wide.

The impact crusher can adjust the discharge granularity in various ways, such as adjusting the rotor speed, adjusting the gap between the impact plate and the grinding chamber. Clearance adjustment can be adjusted mechanically or hydraulically. The hydraulic adjustment system can be used to conveniently adjust the clearance by operating the button or the travel control system on the spot.

-

4the wear of the wearing parts is small, and the metal utilization rate is high.

The wear of the hammer of the impact stone breaker only occurs on the side facing the material. When the rotor speed is normal, the feed will fall to the surface of the hammer (hitting surface), and the back and sides of the hammer will not be worn. Even the wear on the side facing the material is minimal. And the bottom grinding rod is easy to replace. The metal utilization rate of the impact crusher plate hammer can reach 45% -48%.

-

5The replacement of the spare parts of the impact crusher is easy, and the maintenance costs are reduced accordingly.

Only 6 plate hammers are installed on the impact crusher rotor, and the plate hammer can be easily replaced with the designed special tools.

Advantages:

-

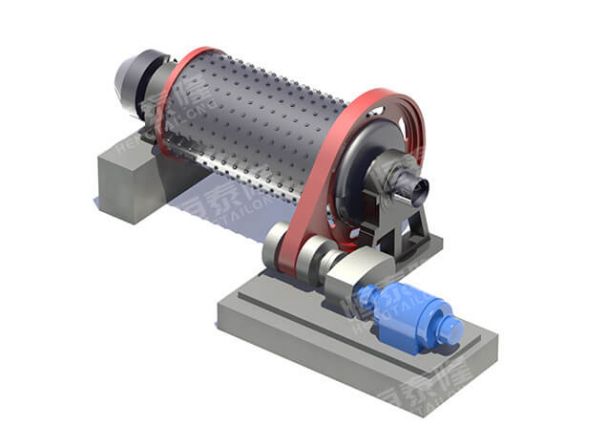

Rotor and blow bar

-

The design of the plate rotor and blow bar meet the requirements of reliable operation, simple loading and unloading and improving the metal utilization rate of the blow bar.The blow bar is generally made of high chromium cast iron, high manganese steel and other wear resistant alloy steel.The rotor of the impact crusher is made of integral cast steel, the structure is strong and durable

-

Liner

-

Our factory has specially designed a special casting process for the lining plate to avoid defects such as blowholes and tracheas that are easy to occur in thin plate casting, which makes the thickness of the casting uniform and the metallographic structure dense. At the same time, a reasonable heat treatment process is designed to ensure not only its high wear resistance but also its good toughness and impact resistance.