- Home

- About Us

- Products

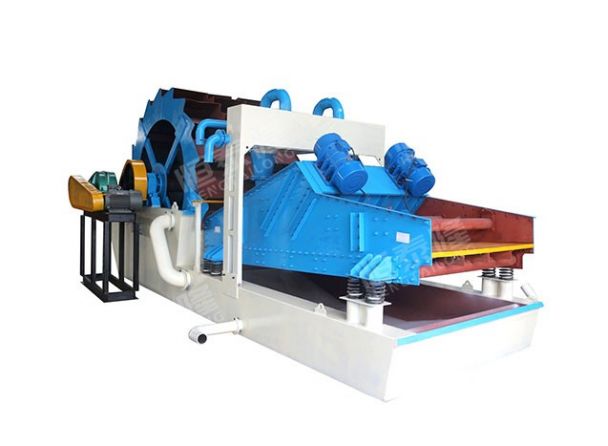

- Stone Crushing EquipmentJaw crusherImpact crusherHammer crusherSpring cone crusherImpact fine crusherReversible crusherDouble rolelr crusherVertical compound crusherSand making machineDouble stage crusherWheel sand washing machineSpiral sand washing machineVibration dewatering screenStone and sand production lineMobile crusher stationhydraulic cone crusher

- Mineral Processing EquipmentRotary ore washerBall millSpiral classifierXJK Flotation MachineSF flotation machineWet Magnetic separatorShaking tablejig machine separatorMining Flotation Separation LinecipCentrifugal concentratorDouble impeller leaching tankspiral chuteconcentratoralluvial sand washing plantgold centrifugal machine

- Drying Equipment

- Environmental Protection Equipment

- Stone Crushing Equipment

- Case

- News

- FAQ

- Contact Us