High Frequency Coal Soil Washing Linear Dewatering Dewater

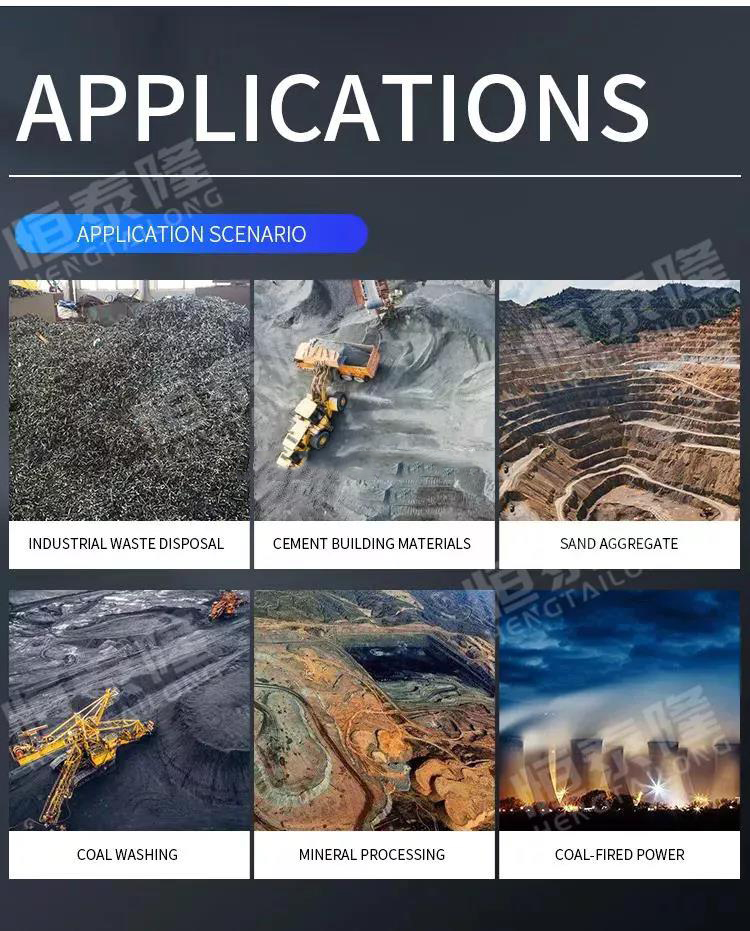

Linear dehydrated medium screen is developed in recent years my company with international quality large-scale screening equipment,

applicable to the raw coal of coal preparation plant, classification ,desliming dehydration, mine sieving,

screening of power plant and coal chemical industry of new energy industry, materials such as separation process .

Linear movement way, the material is not easy to plug mesh, sieve plate than the traditional circular vibrating screen is long,

life is a traditional circular vibrating screen upgrade of choice.

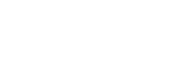

Product Application

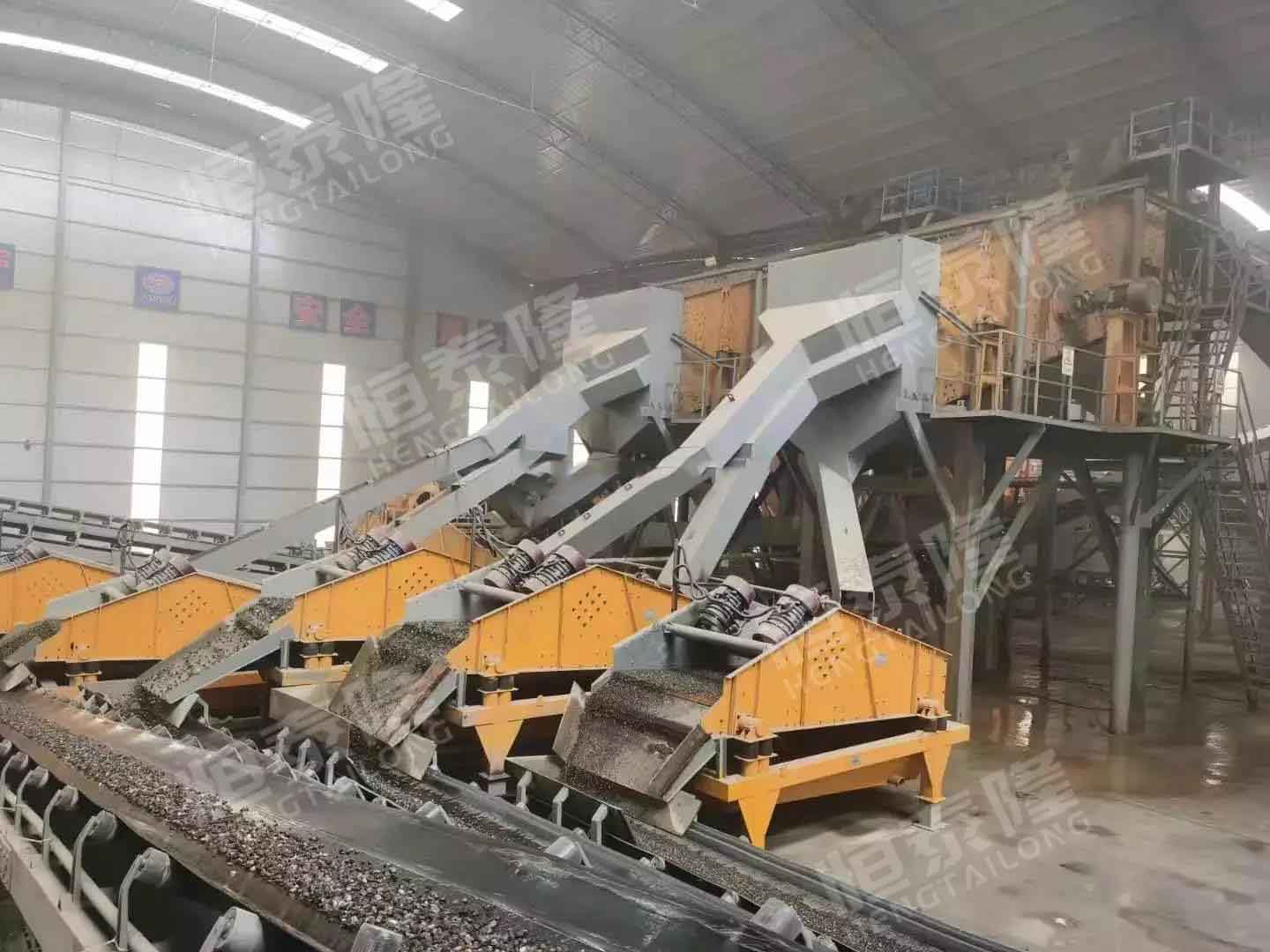

Coal Preparation Plant Dewatering Screen is widely applied for dewatering, desliming, deintercalation,

which can be used to sand and stone washing plant, coal preparation plant, sludge recycling,

mineral processing plant, tailings dry discharge and more.

So it is also called sand and stone dewatering screen, mine dewatering screen, coal slime dewatering screen,

tailings dewatering screen, high frequency dewatering screen.

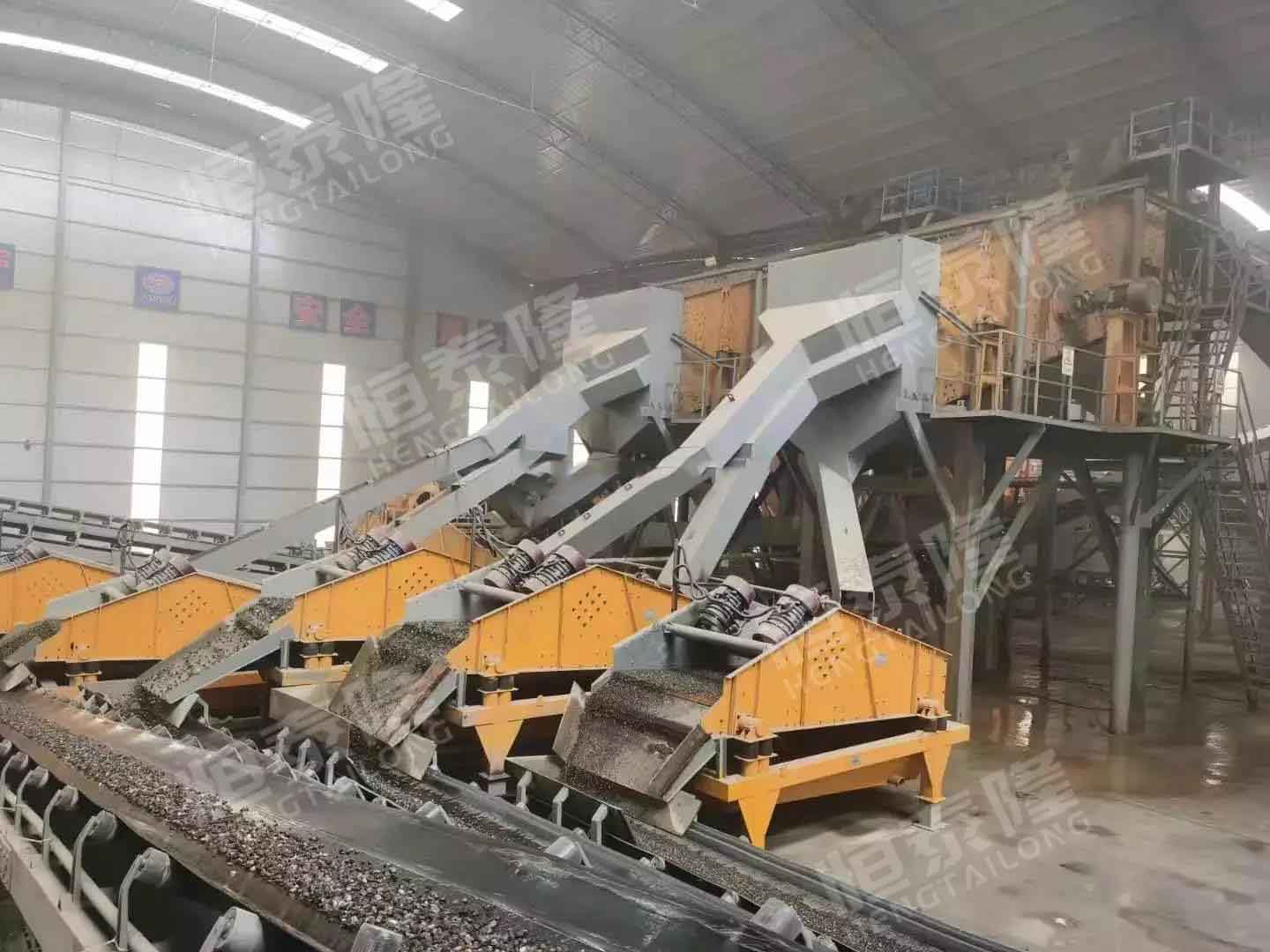

Detailed Images

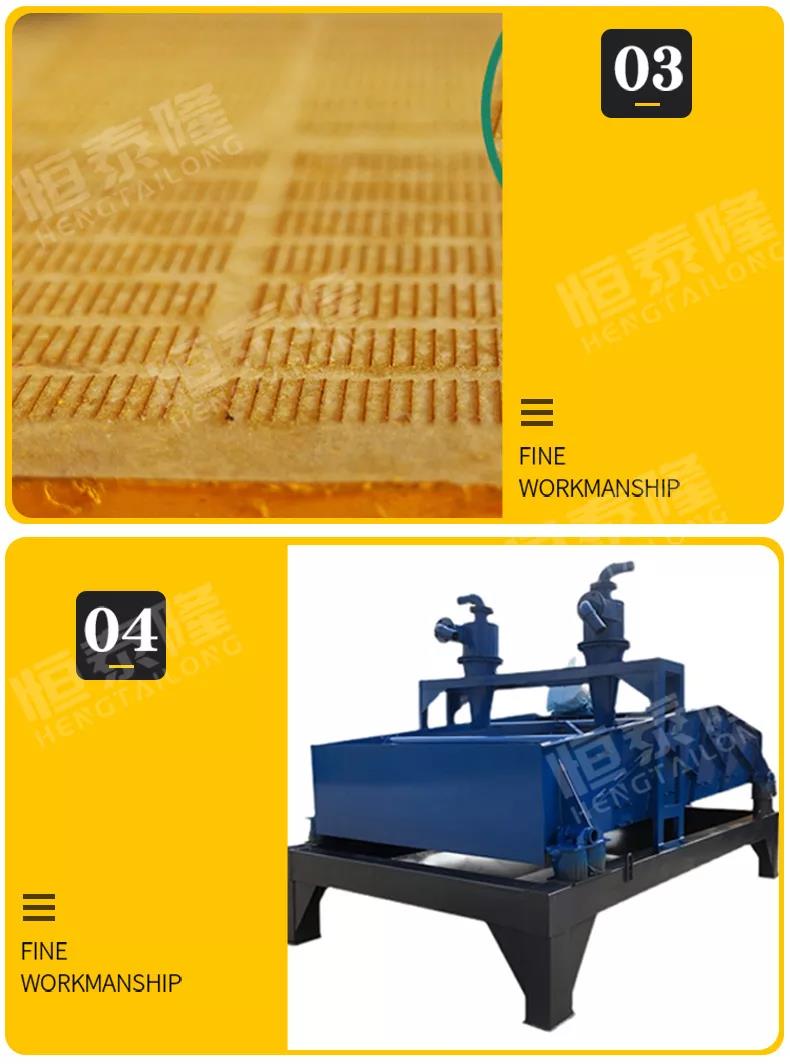

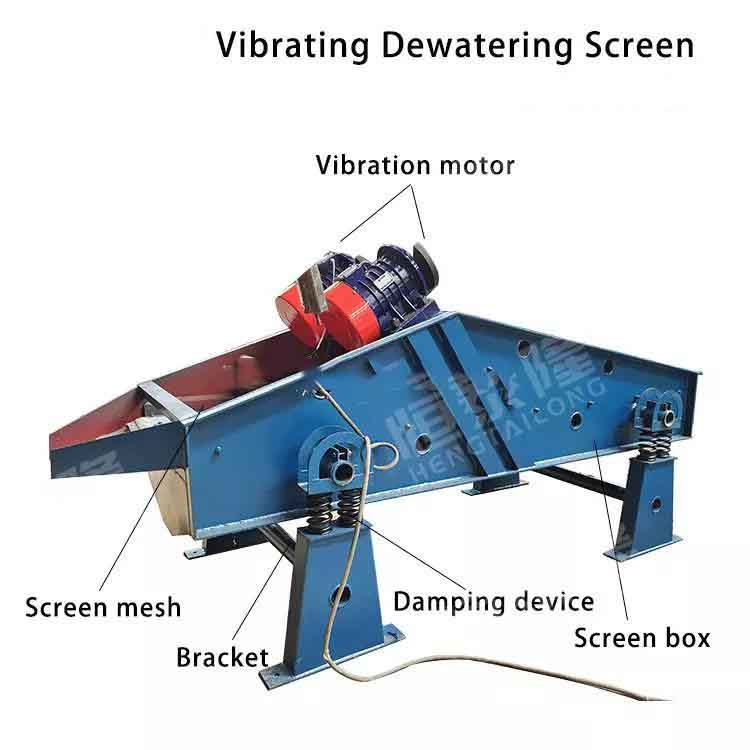

01.COMPONENTS

All components are processed by blasting andpainting and all assembly surfaces are processedby waterproof sealing,

which realizes the welloperation of screen in worse field.Weldless sideplates are assembled by HUCK bolts to ensurezero stress on the structure.

02.EXCITER BEAM

The box exciter beam has the advantages ofstrong strength and light weight .

A furthermachining processing on the assembly surfaceof exciter beam by CNC machine ensures a highassembly quality of screens.

03.CROSS BEAM

Cross beam was made by a special circle pipe torealize strong strength light weight .

The specialolyurethane painting one the surface of crossbeam to realize the erosion resistance andabrasion resistance.

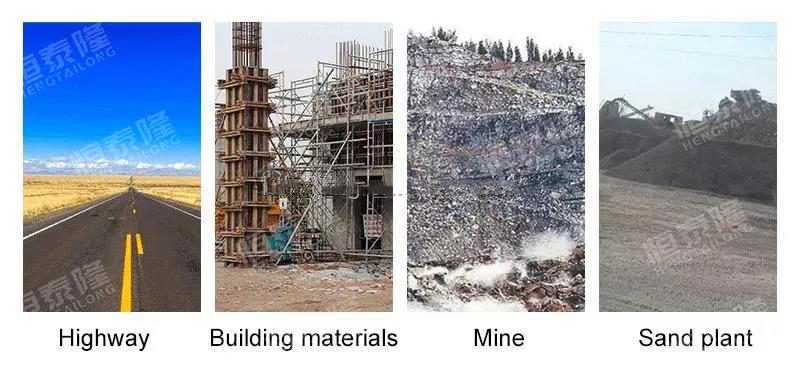

04.SCREEN MESH

High opening area deck with resistance to blockcan realize the good D & R performance and longworking lite .

05.EXCITER

High efficiency exciter use the specialized SKFvibrating bearing with the advantage of strongexciting force , lower noise and longer workinglife.

Working Principle

The feed tailings are evenly fed into the feed inlet of the sieve by the feeding box.

Firstly, about 1/3 of the water is removed at the level of 45 degrees to install the drain screen,

and the combination of the flat sieve plate and the inclined sieve plate is entered.

After the Ministry, the accumulation of materials appeared, the slime particles settled by gravity, and began to form a thinner filter layer,

which in turn prevented the remaining particles from passing through the sieve, so that the filter layer gradually thickened.

The water that fails to pass through the sieve forms a pool in the upper part of the filter layer.

Since the filter layer is thinner here, the water gradually gradually removes under strong motion. Due to the high-frequency low-amplitude vibration state,

the tailings vibrating the filter layer is formed. More and more compact, to the discharge opening, the material forms a filter cake,

the water in the tailings is removed from the screen surface, and the other parts appear on the surface of the material layer due to the capillary action.

It will overflow from the discharge opening, and the surface water will flow to the joint pool.

Features and Benefits

1) High working frequency, high vibration intensity, low moisture content on the sieve, high unit processing capacity,

and high solid recovery when used for tailings dewatering.

2) Using the self-synchronization principle, the motor drives the vibrator through the tire coupling, which has a simple structure and low working noise.

3) Install at a negative inclination angle, and install the sieve surface of the dewatering section at a level of 45 degrees to increase

the dewatering area and promote the dehydration of the material as soon as possible to form a filter layer.

4) In order to adapt to the difference in the properties of different tailings, the amplitude of the screen can be adjusted.

The method is to adjust the angle between the main and auxiliary eccentric blocks to meet the dewatering effect of tailings with different properties.

Great efforts to achieve. Excellent process effect.

5) The side plate and the beam are connected by torsion-shear type high-strength bolts,

and there is no weld seam, which avoids the problem of side plate cracking caused by welding stress.

6) The vibrator is a block eccentric unit structure, which is easy to disassemble and maintain.

7) The bearing adopts special bearing for vibration equipment to avoid premature damage of bearing heat.

8) The mesh surface adopts polyurethane elastic screen surface, high opening ratio and elasticity, which is beneficial to dehydration.