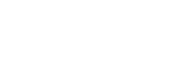

Gold Ore Iron Copper Graphite Mining Thickener Machine for Concentrates and Tailings Dewatering

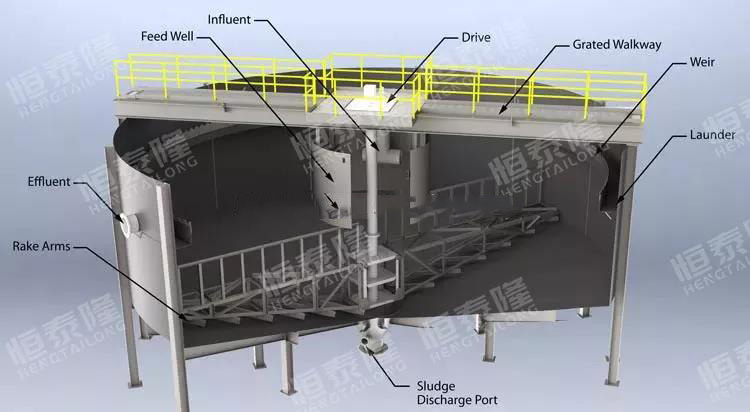

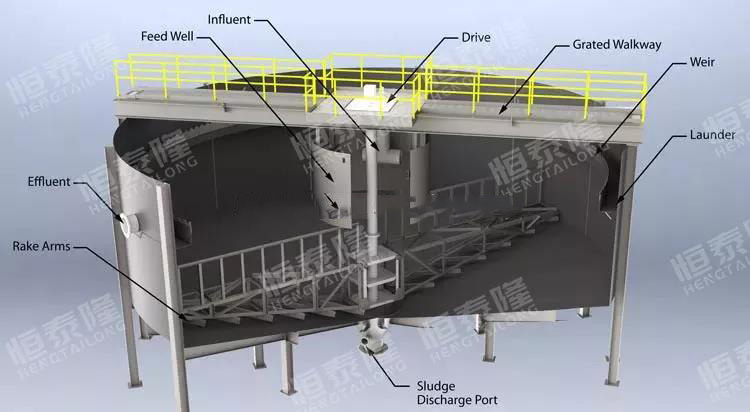

Thickener is a solid - liquid separation equipment based on gravity sedimentation.

The pulp containing solid weight of 10%~20% can be concentrated into the bottom-flow pulp containing solid content of 45%~55% by gravity sedimentation,

and the thickened bottom-flow pulp can be discharged from the bottom flow port of the thickener by means of

the harrow installed in the thickener for slow operation.The upper part produces a cleaner clarifying liquid (overflow),

which is discharged from the annular chute at the top.

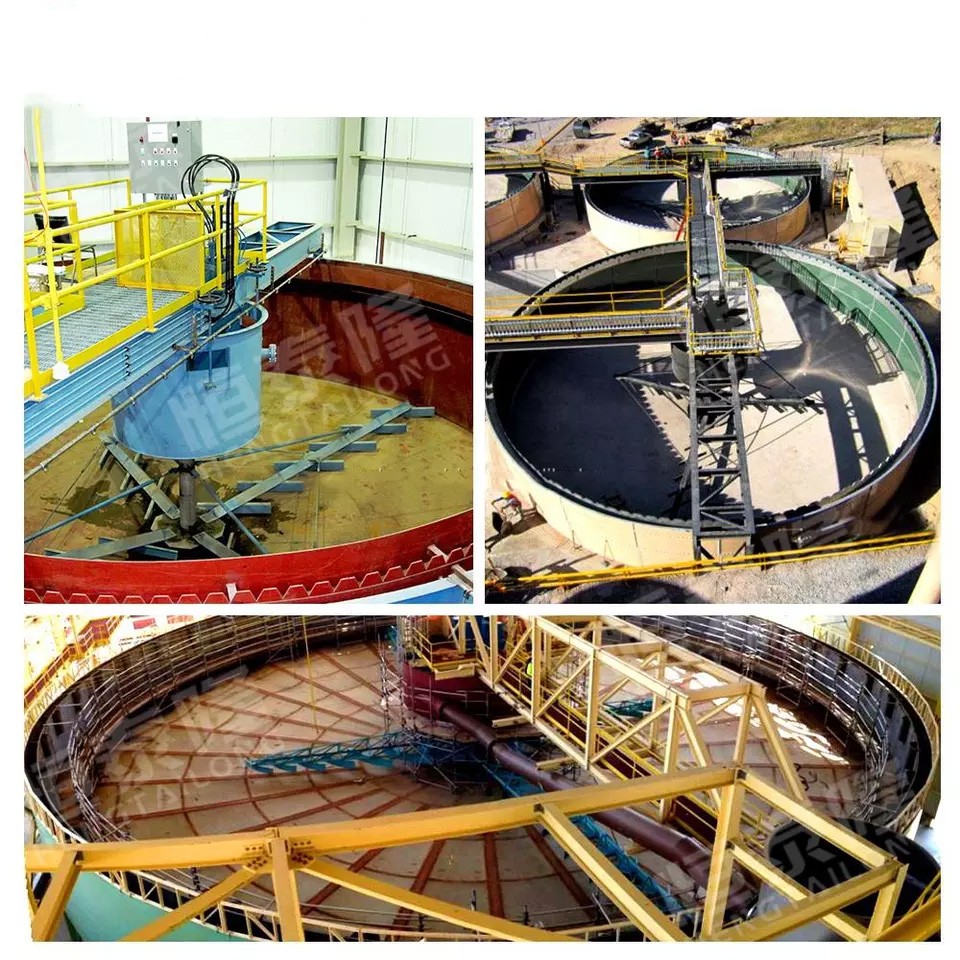

Product Application

The thickener widely used in metallurge, mining, coal, chemicals, building materials, environmental protection and other departments to concentrate sludge,

waste water and waste slag, improving utilization and underflow transport concentration and protecting the environment.

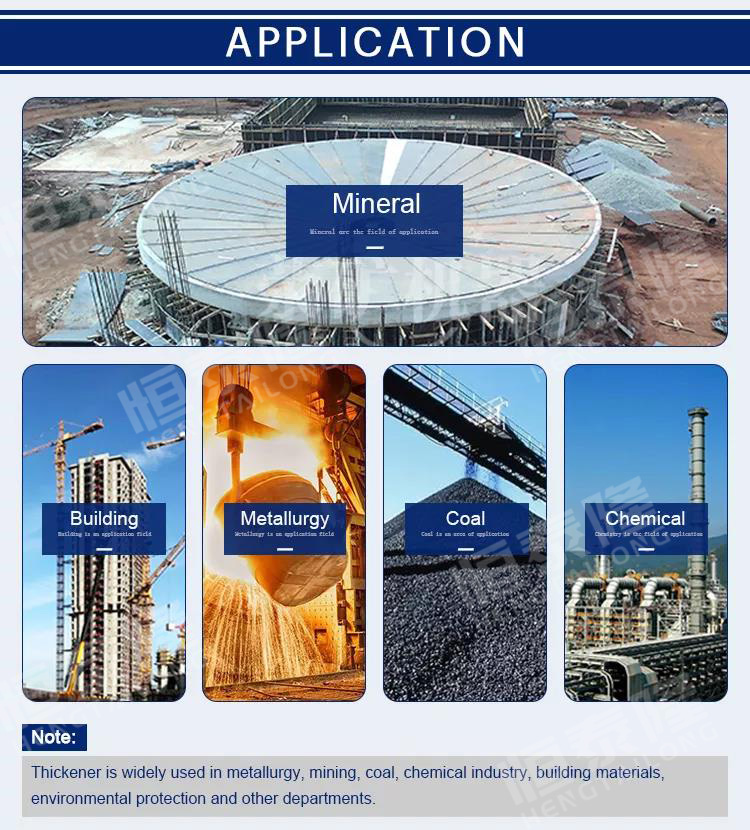

Working Principle

Mining thickener consists of round thickener and harrow scrapping machine, the solid particles suspend in thickener settling by gravity,

the pulp in the upper turn into clean water, so that the separation can be realized.

Slime that sediment in the bottom of the thickener is discharged by the harrow scrapping continuously, and clean overflow from the upside.

Main Features of mining machinery gold mining thickener machine

1.Deaeration cell is provided to prevent solid particles from attaching to bubbles so that solid particles can fall like a parachute.

2.The mineral-feeding pipe is lower than the pulp surface; it prevents the air to be brought in while feeding.

3.The feeding sleeve is moved to a lower position and receiving plate is equipped.

Therefore, the fed slurry fall evenly and steadily, preventing rolling phenomena because of the residual pressure from feeding.

4.Inner overflow weir is equipped to make the pulp flow on pre-designed route, avoiding short circuit, enlarging the sedimental area.

5.Inner overflow weir is made into indented shape, eliminating part suction phenomena induced by unleveled overflow weir.

6.The peg linear is changed from oblique lines to curves. So the discharging underflow has higher density, and treatment capacity is enhanced.

Product Advantages

1.Add a degassing tank to avoid solid particles adhering to the bubble, similar to "parachute" deposition.

2.The feeding pipe is located below the liquid level to prevent gas from being brought into the mine.

3.The feeding sleeve moves down and the receiving plate is set to make the feed pulp fall evenly and steadily,

effectively preventing the phenomenon of turning over caused by the overpressure of the ore.

4.Add an internal overflow weir to make the material flow according to the specified stroke and prevent the "short circuit" phenomenon.

5.The overflow weir is changed to zigzag shape, which improves the suction phenomenon of local drainage caused by non-horizontal overflow weir.

6.Change the rake tooth shape from slant to curve, so that the pulp not only to the center of the rake, but also gave a "backlog" to the center of the force,

so that the discharge of ore bottom flow concentration is high, thus increasing the processing capacity.