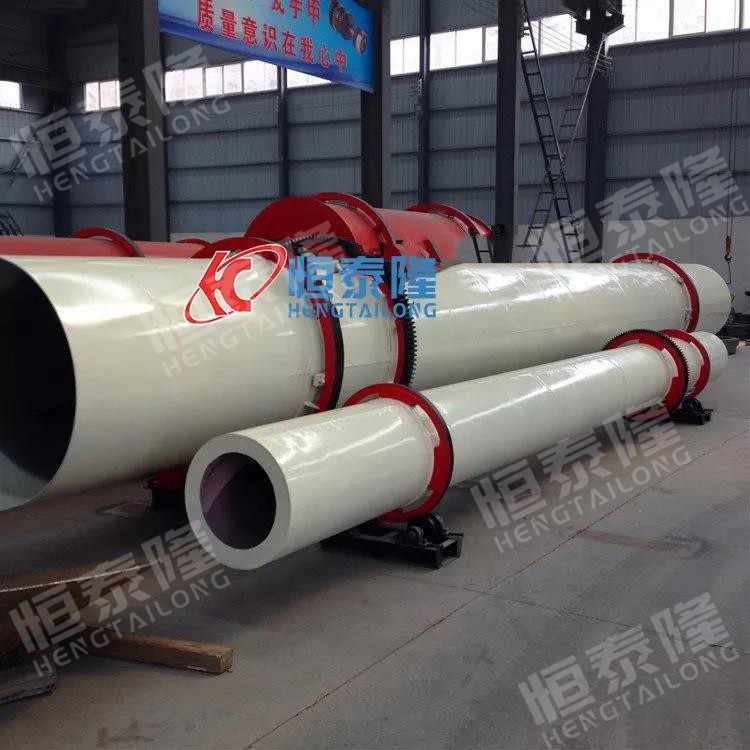

Enenry Saving Copper Ore Coal Concentrate Rotary Dryer Machine

Sludge drying is an intermediate sludge treatment process that consists of evaporating the water in the sludge.

Sludge drying is the process of transforming sludge into useful products or green fuel. Removal of water reduces storage volume and transportation costs.

It significantly reduces the volume and weight of the sludge so that it is easier to recover.

Sludge is the industrial waste generated during the production process of municipal sewage processing.

Because sludge has many disadvantages such as high moisture content, high viscosity, high water holding capacity, and low calorific value.

It is difficult to achieve industrial utilization.

Hengtailong operated a series of technical researches on the current market situation of sludge treatment and the characteristics of sludge in various regions.

Hengtailong Company concentrating created a new generation of sludge rotary drum drying system, drying product moisture can be reduced less than 25%,

it totals achieved the standard of sludge landfill and further incineration processing conditions.

The technology of equipment gets absolutely mature enough, also it has a stable capacity for operation and very convenient to operate and maintain.

Detailed Images

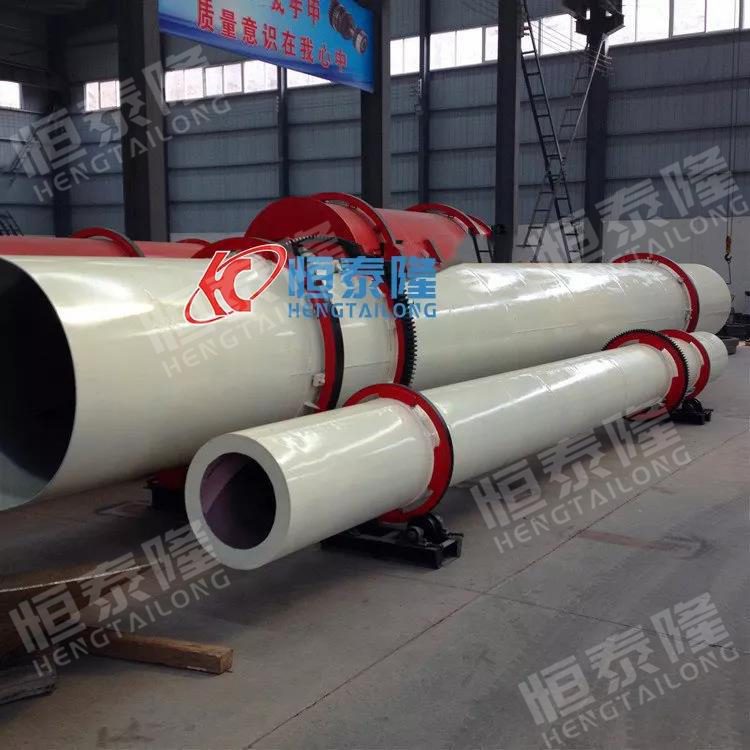

Point 1-Steel Plate Selection

Chemical analysis was carried out on the material inspection, according to the requirements of GB700-2006,

dryer drum thickness < = 20 mm we use Q245 - A, > 20 mm we use Q245 - B;

According to the GB/T 2970-2004 class ii, the range of 60 mm weld edge every

board before cutting for ultrasonic flaw detection.

Point 2-Dryer Drum Welding

The dryer cylinder section for toroidal welding, longitudinal along the entire circumference of not more than two weld article number,

and shell welds shall be full, the minimum is not lower than the parent metal surface, the top should not be higher than 3 mm,

feed plate weld should be smooth.Weld edge bite depth should not be greater than 0.5 mm, continuous length should not be greater than 100 mm,

should not exceed the total length of each weld bite edge which 10% of the weld length.

Point 3-nspection

Examination all the parts according to the drawing after processing completion.

Spraying primer, rust preventing paint, and heat resistance paint.

Rotary Dryer Application

The Poultry manure dryer machine is Yuhong company according to the market demand professional design and developed one type new rotary dryer,

this new type dryer suitable to drying the material moisture content at 50-65%,such as poultry manure,chicken manure,

bird manure,pig manure,cow manure,cattle manure,sheep manure and other material.Depended on the different characteristic of each type of raw materials,

different capacity, application requirements, cost control, automation degree, optimize the drying process technology,working conditions on site and other things,

we can design the drying process.Yuhong Company recommended product:this poultry manure rotary drum dryer unit capacity is larger,high efficient,

saving energy,covers area is more less, it can saving energy more than 50% than ordinary dryer,it can maximize saving energy and drying costs.

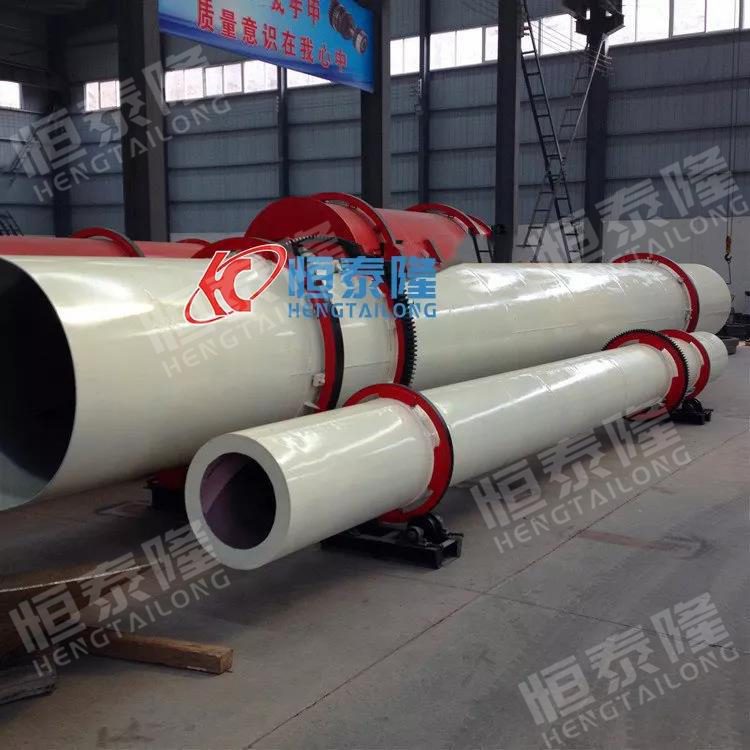

Working Principle

Material to be dried enters the rotary drum dryer, and as the dryer rotates, the material is lifted up by a series of internal fins lining the inner wall of the dryer.

When the material gets high enough to roll back off the fins, it falls back down to the bottom of the rotary dryer, passing through the hot gas stream as it falls.

This gas stream can either be moving toward the discharge end from the feed end (known as co-current flow) of the rotary dryer,

or toward the feed end from the discharge end (known as counter-current flow) of the dryer.

The gas stream can be made up of a mixture of air and combustion gases from a burner,in which case the rotary dryer is called a direct heated dryer.

Alternatively, the gas stream may consist of air or another (sometimes inert) gas that is preheated.

Main Features

1.Great drying effect. Wet materials are highly separated in hot flow. The effective drying area is approaching the total surface area of particles.

2.The design of heat conduction pipe is simple, space-saving and convenient for maintenance and repair.

3.Short drying period. High efficiency and energy saving.

4.Large output and high heat efficiency. For unbound water, the heat efficiency can be as high as 60%.