diesel engine small gold mine coal stone qranite two stage hammer crusher machine

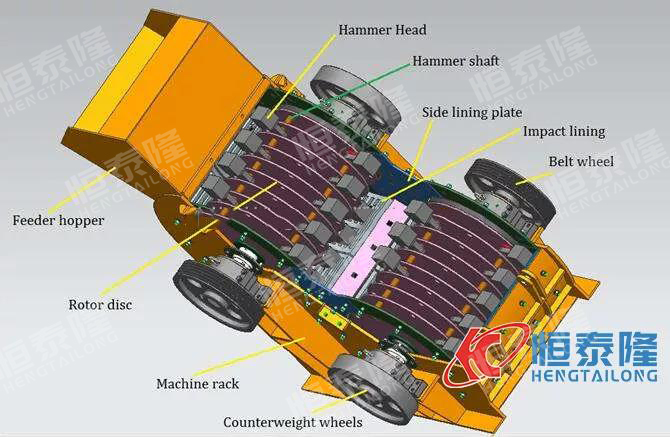

Two-stage crusher is new type raw material crusher which is also called two-rotor hammer tertiary crusher.This machine getsover the shortcomings of refractory discharging because of the high content of the raw material and has the advantage of production efficiency and fine crushing.This machine is suitable for crushing feldspar,limestone,slag in brick plant,construction wastes and so on, thus solving the problems of crushing high-humidity materials such as gangue and coal cinder which are often used as addictive materials and fuel and for producing standard brick and air brick.This machine is equal to the combination of two hammers and the two sets of rotors run together.

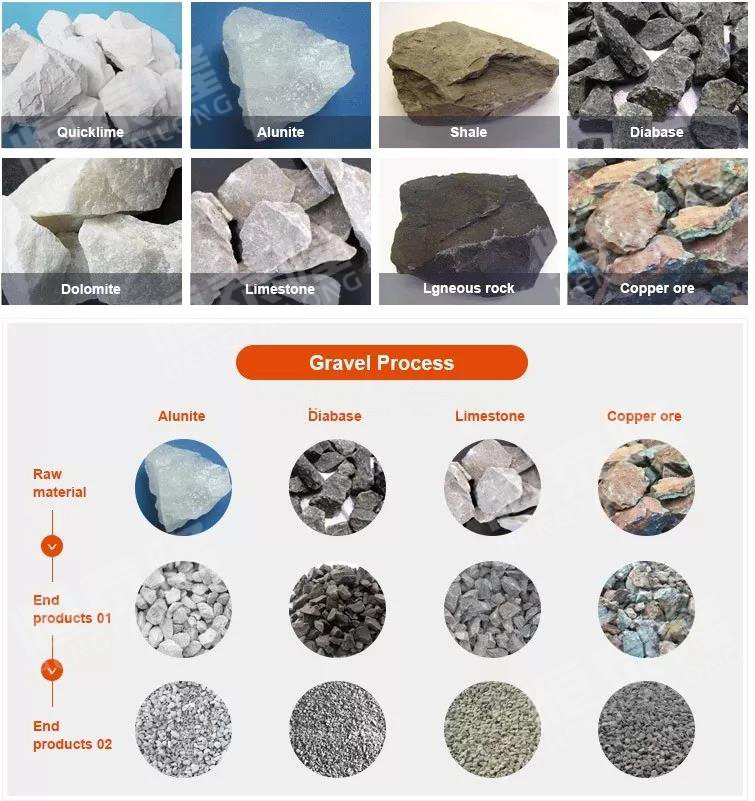

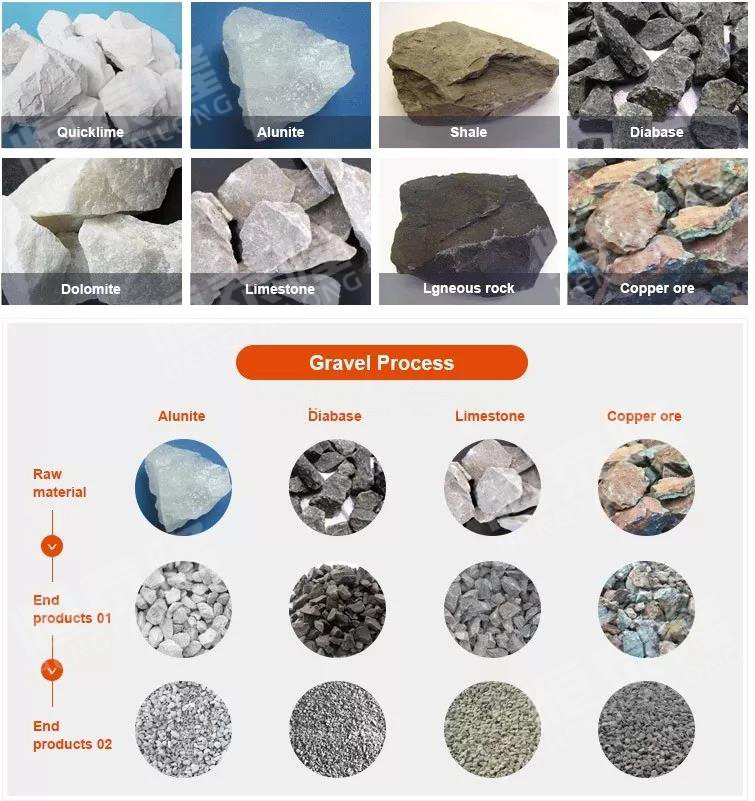

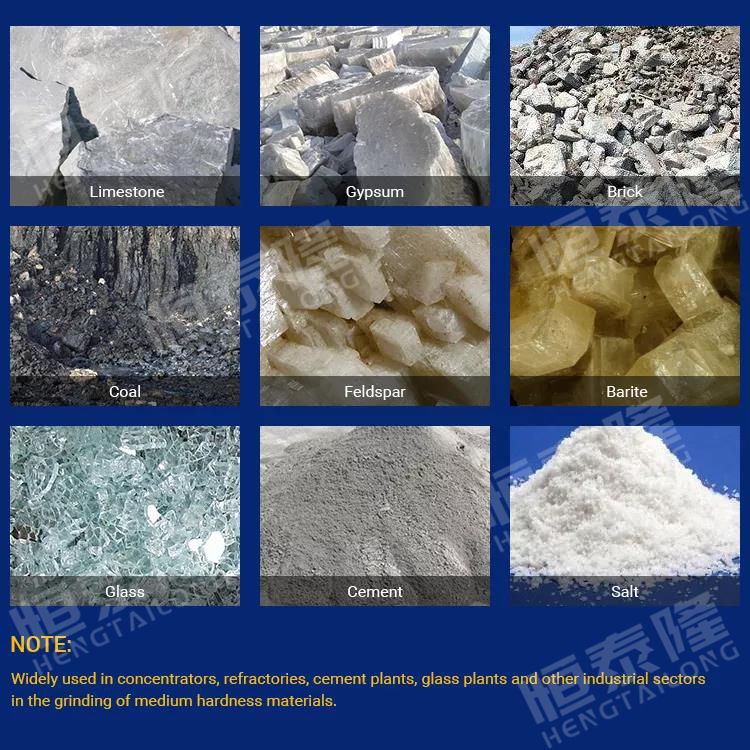

Product Application

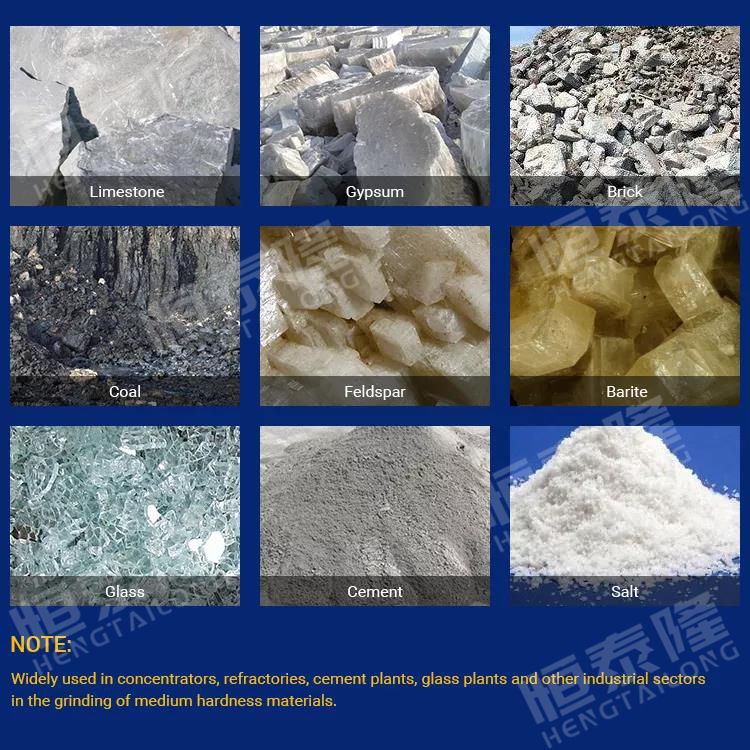

Double stage crusher is suitable for crushing calcite,limestone,coal slag,furnace slag,ore slag in the brick plant,construction wastes,shale,coal gangue,and so on,thus solving the problems of crushing high-humidity materials such as gangue and coal cinder which are often used as additive materials and fuel and for producing standard brick and air brick. thus solving the problems of crushing high-humidity materials such as gangue and coal cinder which are often used as additive materials and fuel and for producing standard brick and hollow brick.In fact, double Stage Crusher is the same as two Hammer Crushers combining together reasonably.Two rotors are applied at the same time in this machine.

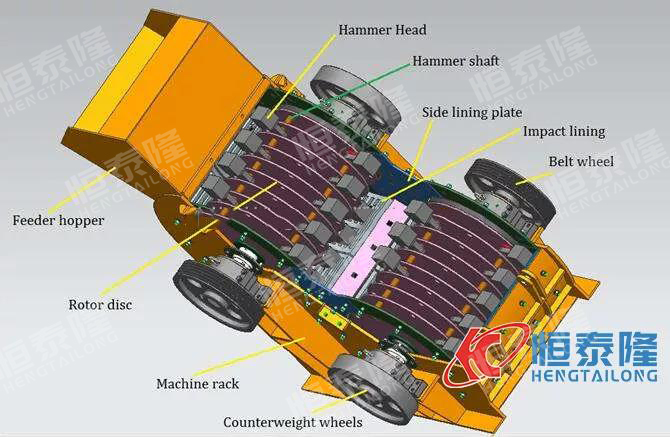

Product Details

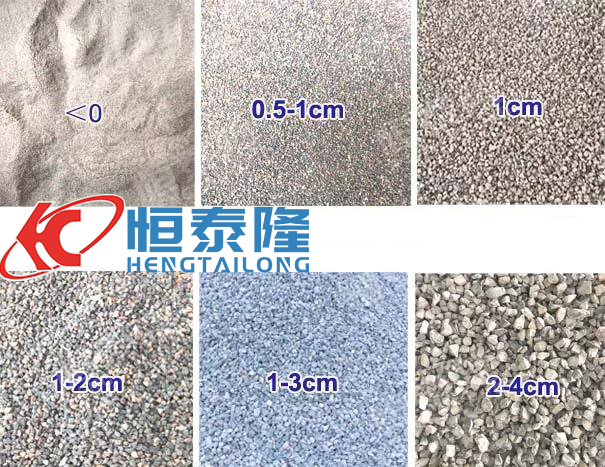

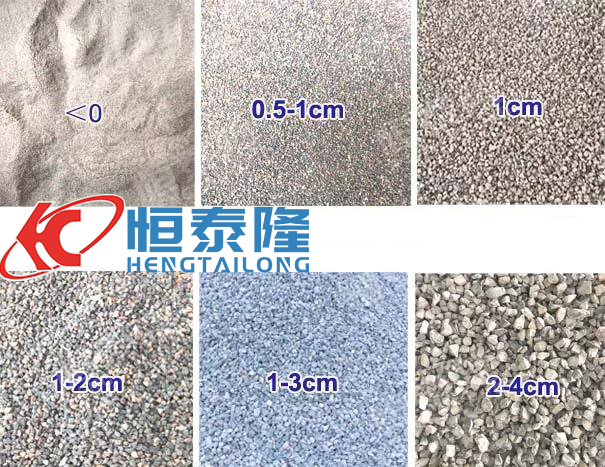

1.This series of crusher continuously crushes materials through two rotors without grating bar device and all kinds of wet slag can be crushed.Even the materials that are just got out from water can be crushed and there will be no blockage.To control the material size, the workers can just adjust the gap between the two crushing hammers.As for the common crushers, since the materials often stay in the crushing chamber and block the it, so that the abrasion of the relevant spare parts will be intensified,but this series of crusher can totally avoid this.2.Two-stage crusher adopts high alloy wear-resisting hammer, and the hammer and hammer handle can be used together,so that when the hammer is abraded,the workers can just change the hammer without changing the hammer handle.

Working Principle

There are two rotors rotate reversely.The materials will be crushed by the first rotor, and then uncrushed material will drop to the next high speed rotating rotor,the material will be crushed for another time by the hammer driven by the rotor.The materials in the cavity impact with each other with high speed,the final crushed material will be discharged directly.

Main Features

The factory price small scale industry stone crusher machine can crush glass,bottles,mineral ores,gangue,coal cinder,metal,clay,shale,small stones and pebbles.After the hammer weared and teared, the gap between the hammer and the liner-plate become large and so does the materials size,at this time adjustment the hammer from the middle to the liner-plate,make the distance between them become shorter,so the machine can be continued to used,which reduces the investment and the costs.